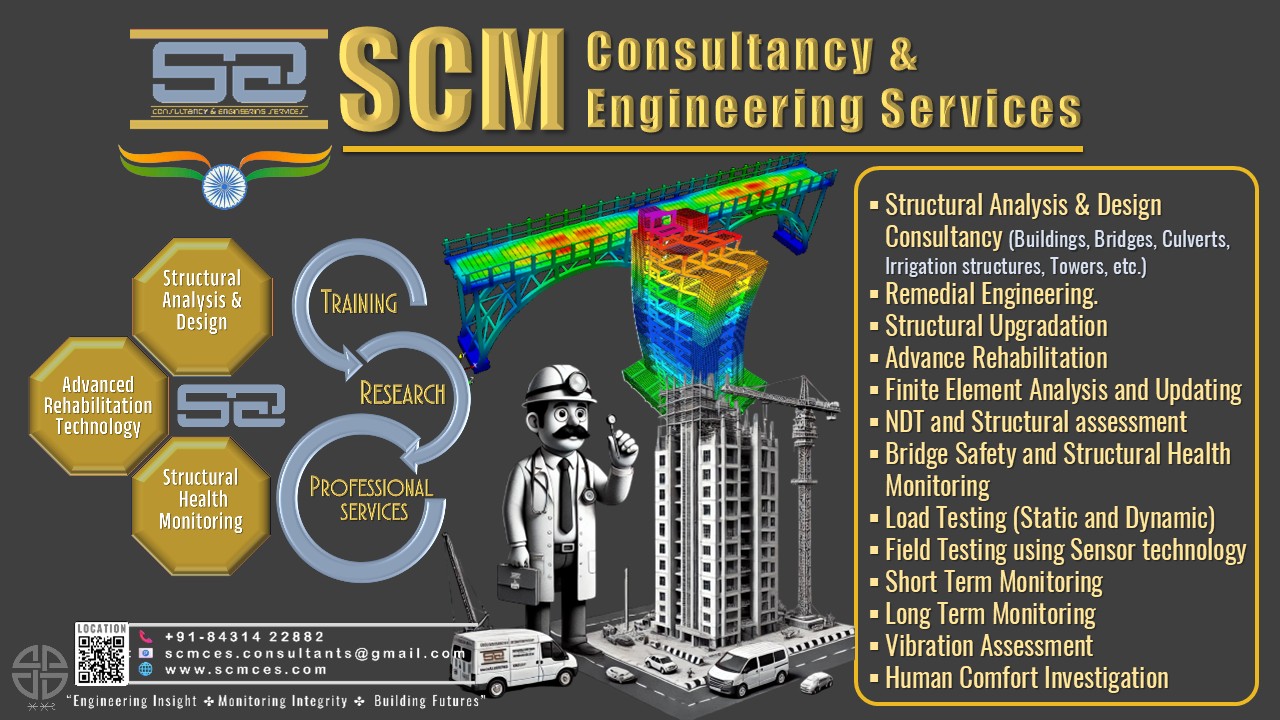

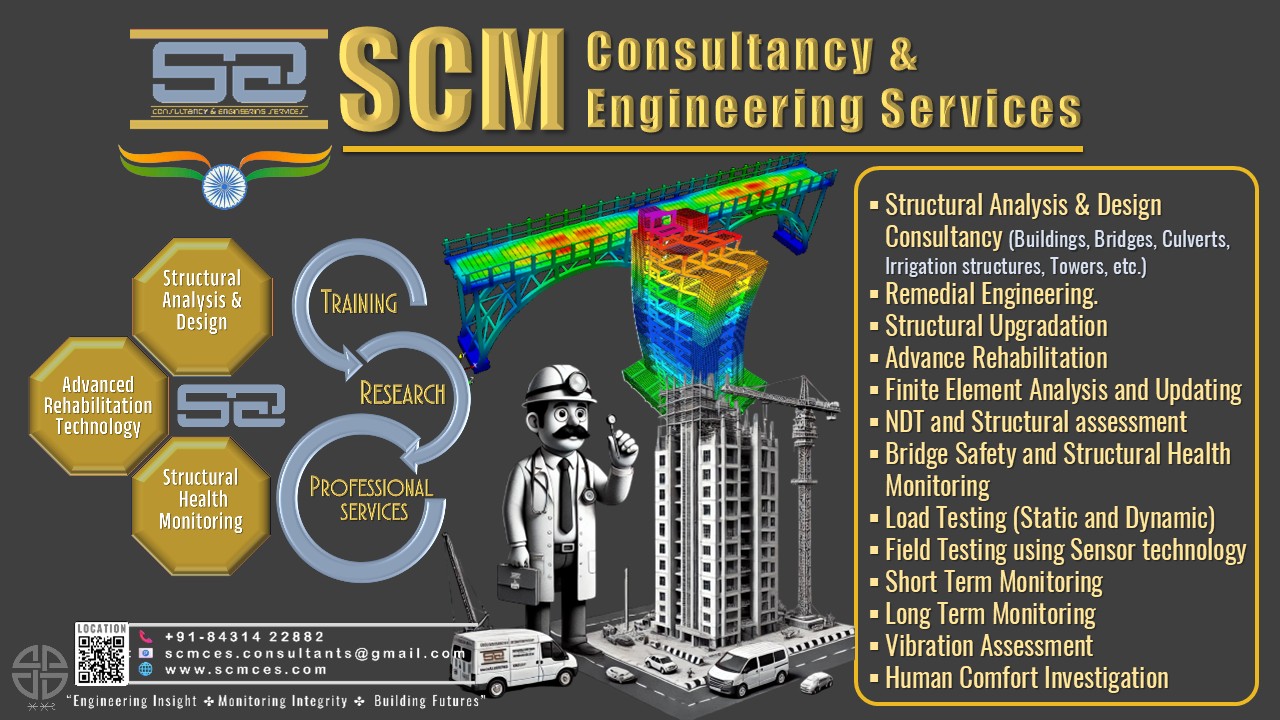

SCMCES - Structural Health Monitoring (SHM) Solutions

✤ Protecting sensitive infrastructure. ✤ Extending service life. ✤

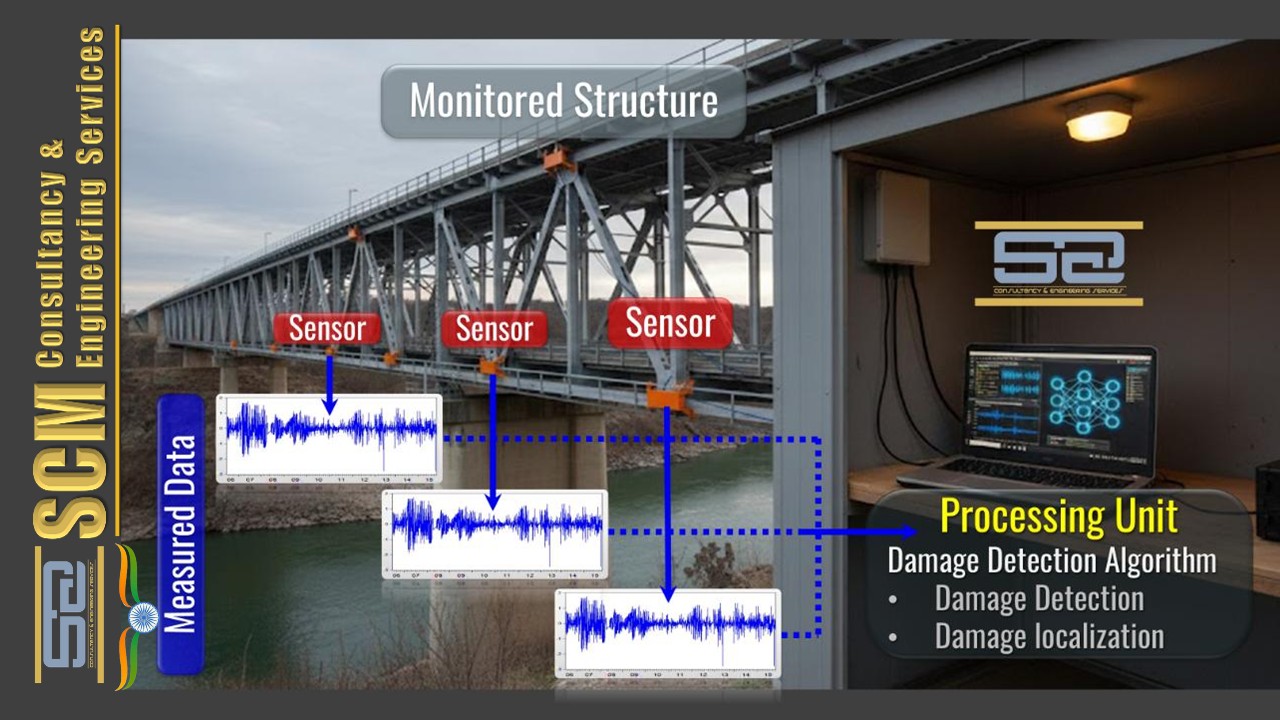

Structural Measurement & SHM (Sensor-based)

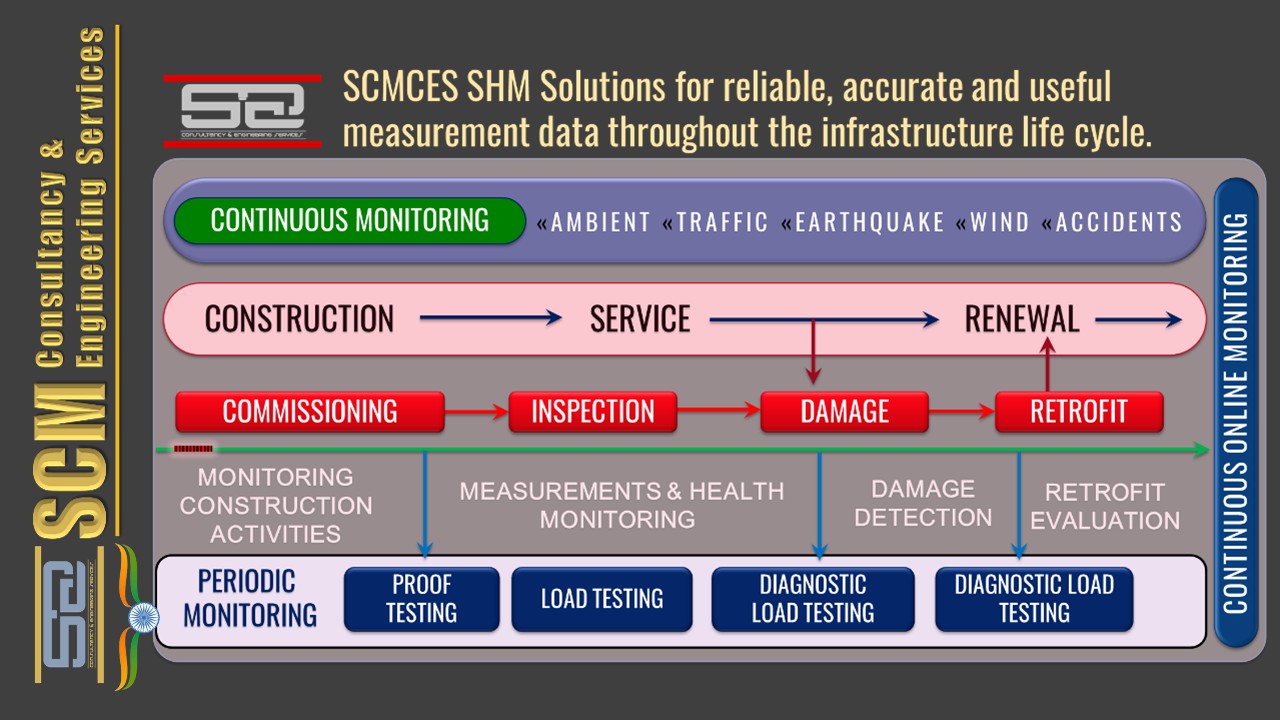

- Recommend instrumentation scheme for Structural health monitoring

- Monitoring and measurement of structural and ambient parameters using sensor technology

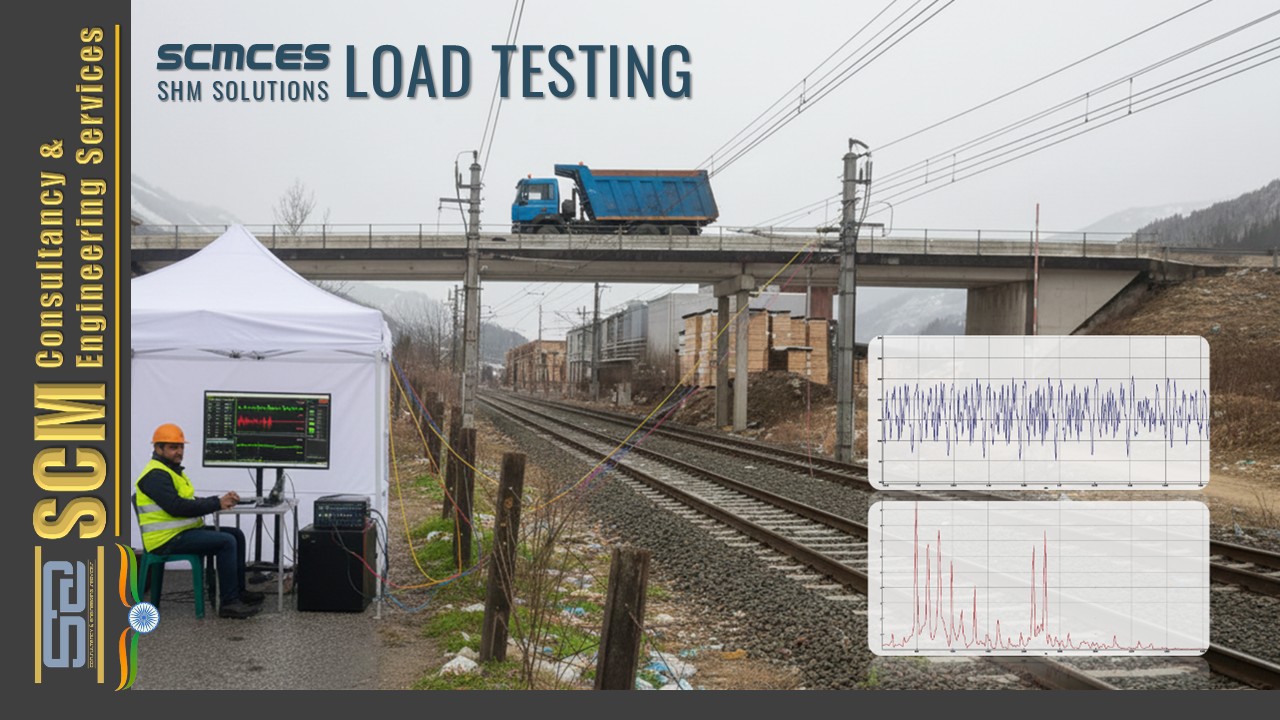

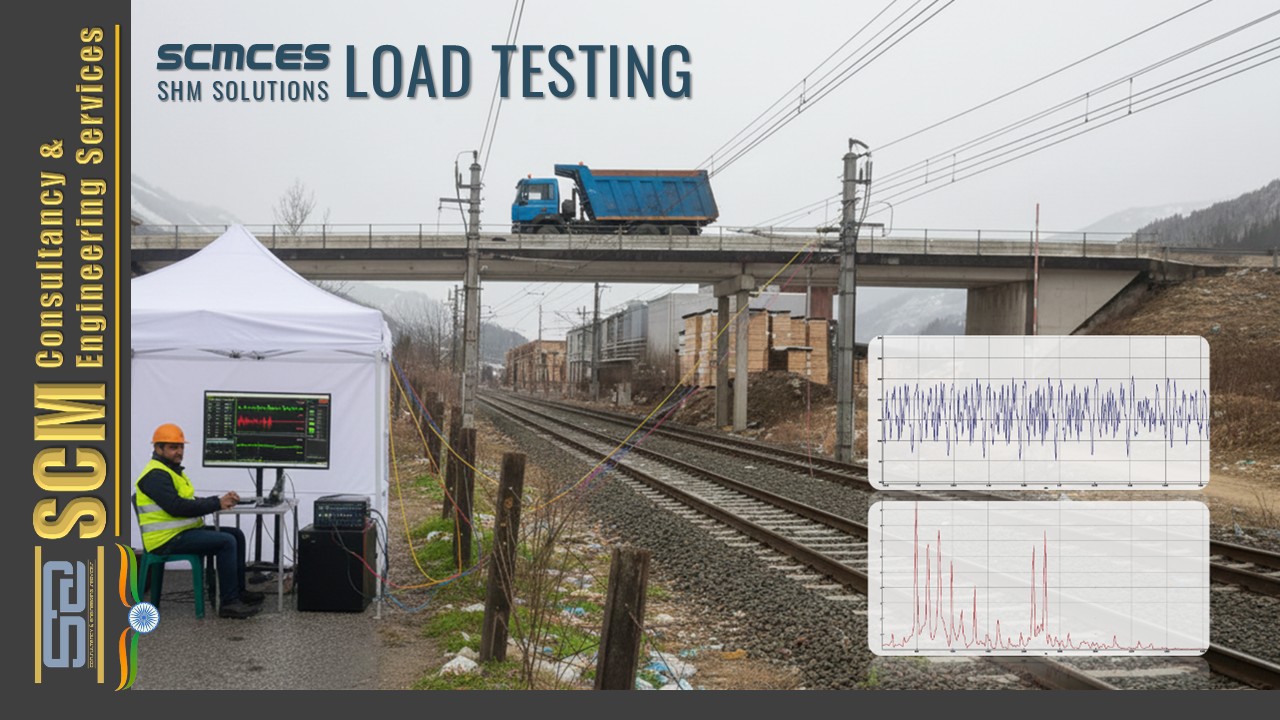

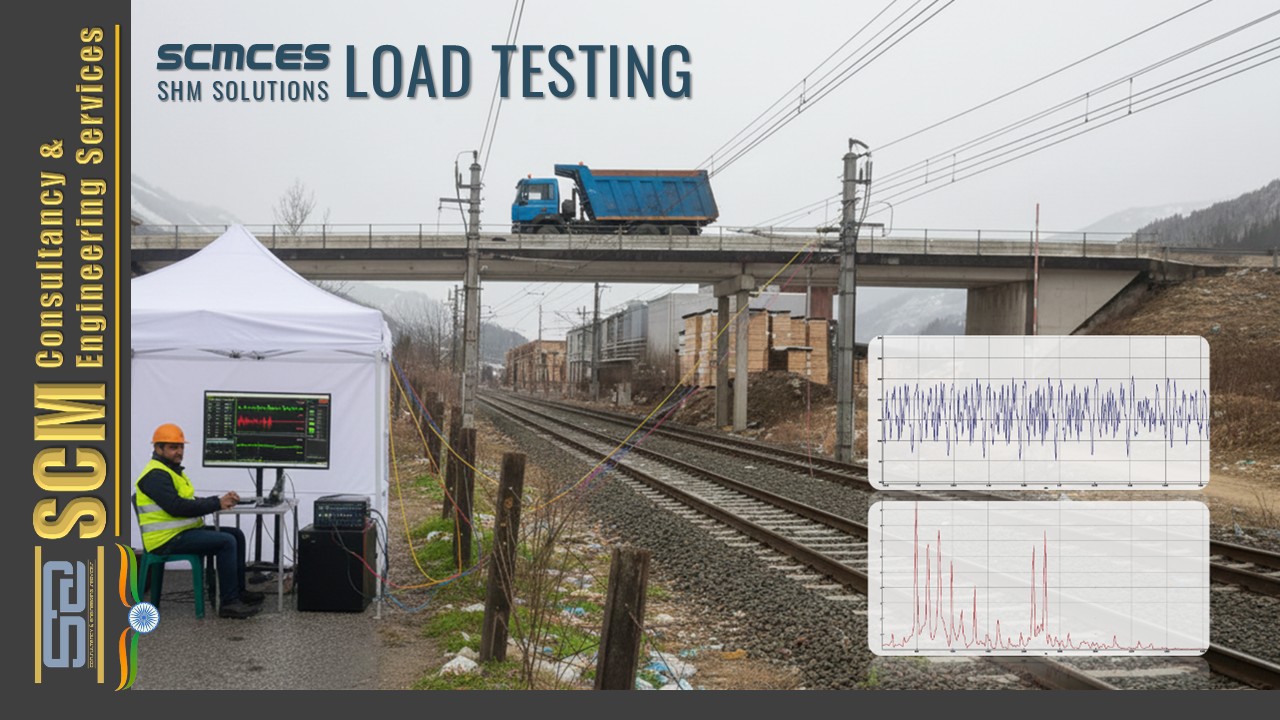

- Load testing (static and dynamic)

- Short term & long term monitoring

- Site specific live load estimation

- Behavioral testing Bridge evaluation and rating Field testing / strain gauging to determine site and structure specific stress cycle information

- Assessment of fatigue damage

- Remaining life estimation.

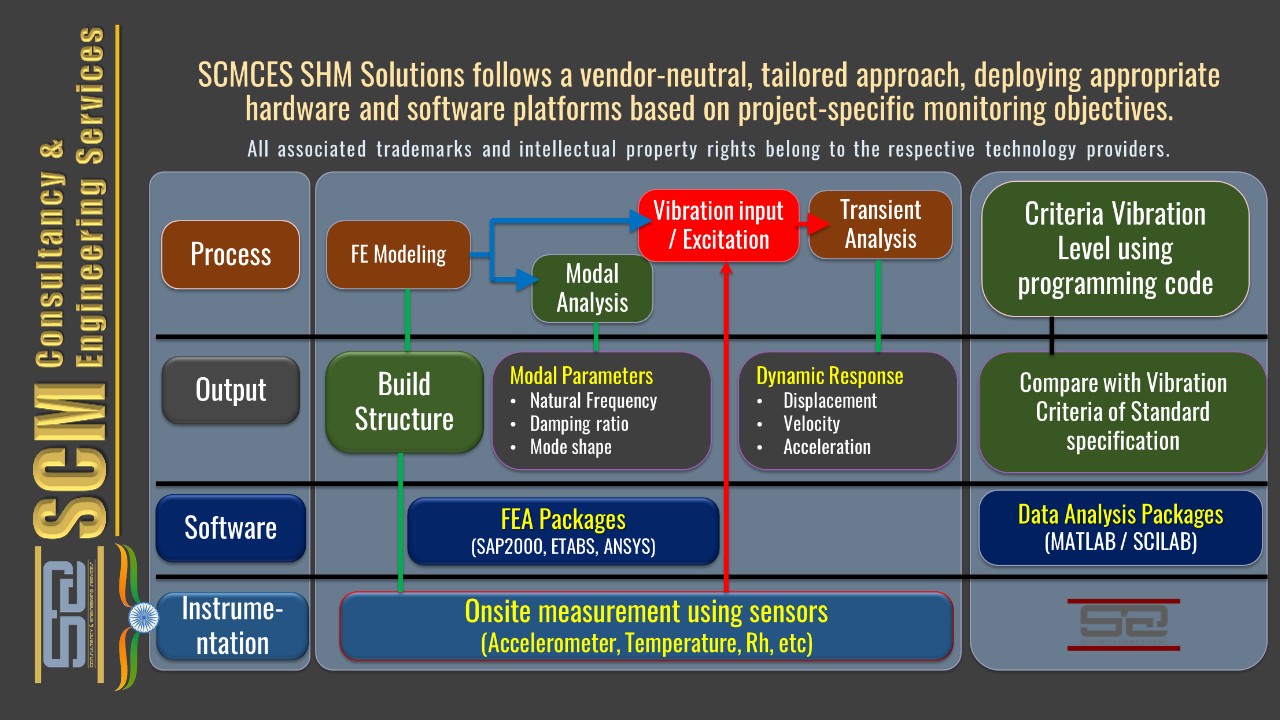

- Analytical structural assessment including finite element analysis

- Training on Structural Health Monitoring (SHM) application to civil infrastructure

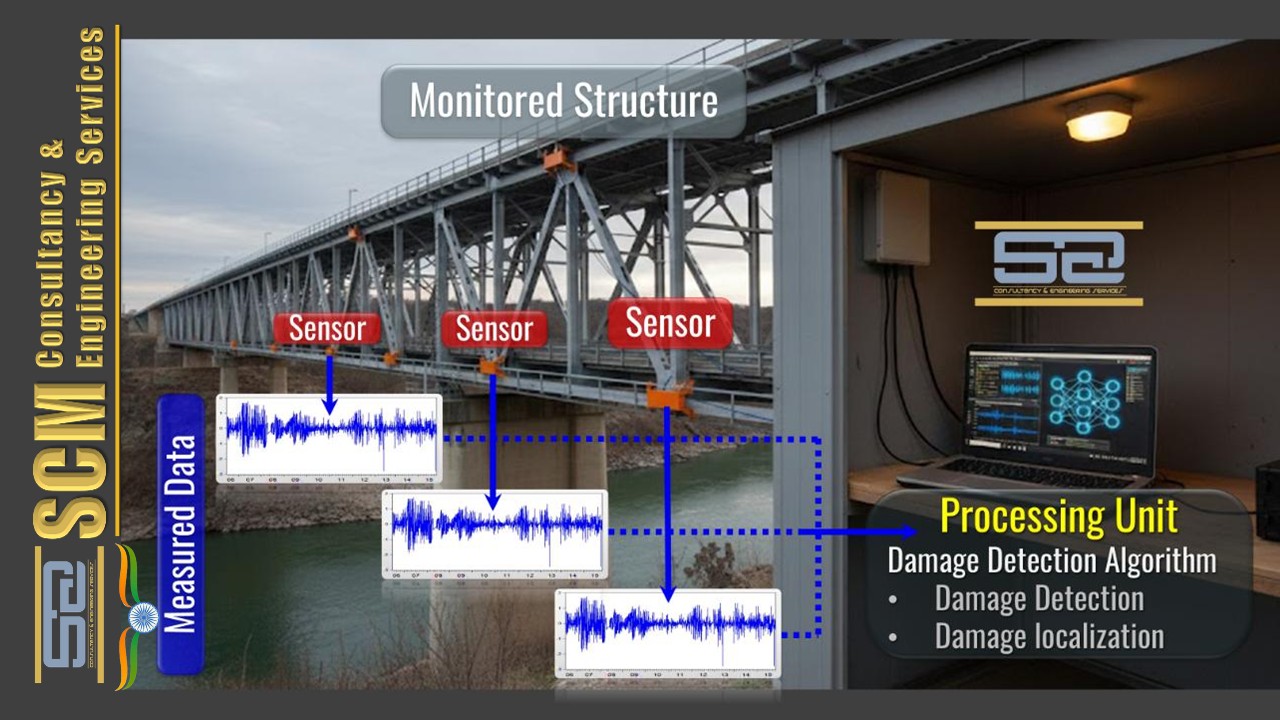

Operational Modal Analysis (OMA)

Where controlled excitation is difficult, OMA uses ambient/operational vibrations to estimate modal parameters (natural frequencies, mode shapes, damping) and track changes for condition assessment.

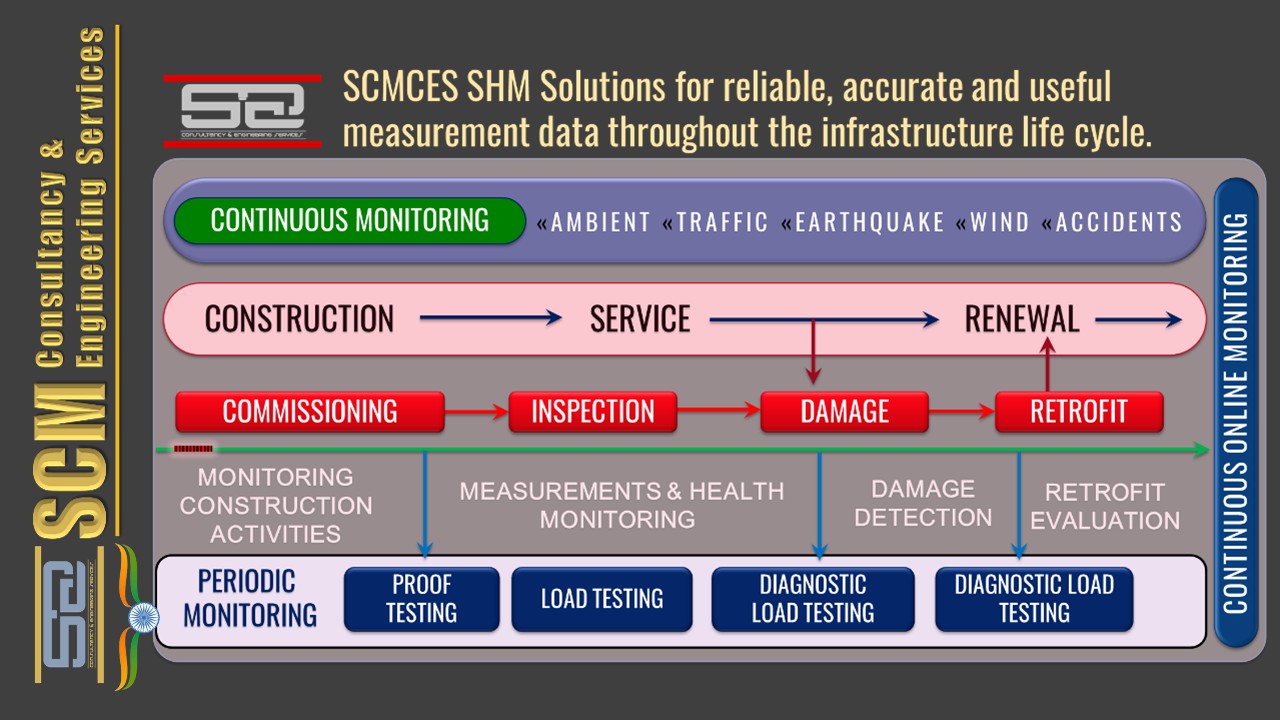

Structural Health Monitoring (SHM) Services

SCMCES provides advanced Structural Health Monitoring (SHM) services to help asset owners, consultants, and authorities monitor, assess, and extend the service life of civil infrastructure such as bridges, buildings, industrial structures, and critical facilities.

Our SHM solutions combine sensor technology, field testing, data analytics, and engineering judgment to deliver reliable, decision-oriented insights—not just raw data.

Why Structural Health Monitoring Is Essential

Civil infrastructure is increasingly subjected to:

- Aging and material degradation

- Heavy traffic and changing live loads

- Machine-induced and environmental vibrations

- Seismic activity and extreme weather

Structural Health Monitoring enables early detection of performance issues, reduction of unexpected failures, and optimization of maintenance and rehabilitation strategies—making it a critical tool for modern infrastructure management.

Our Structural Health Monitoring Solutions

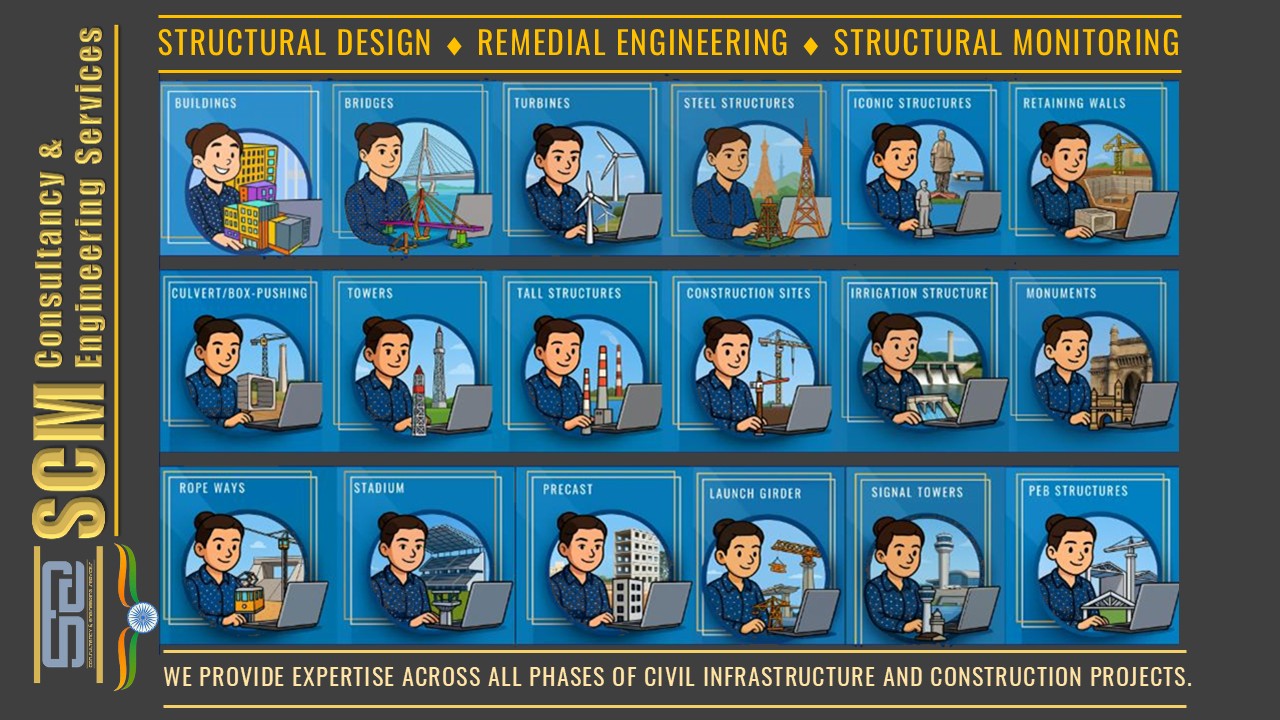

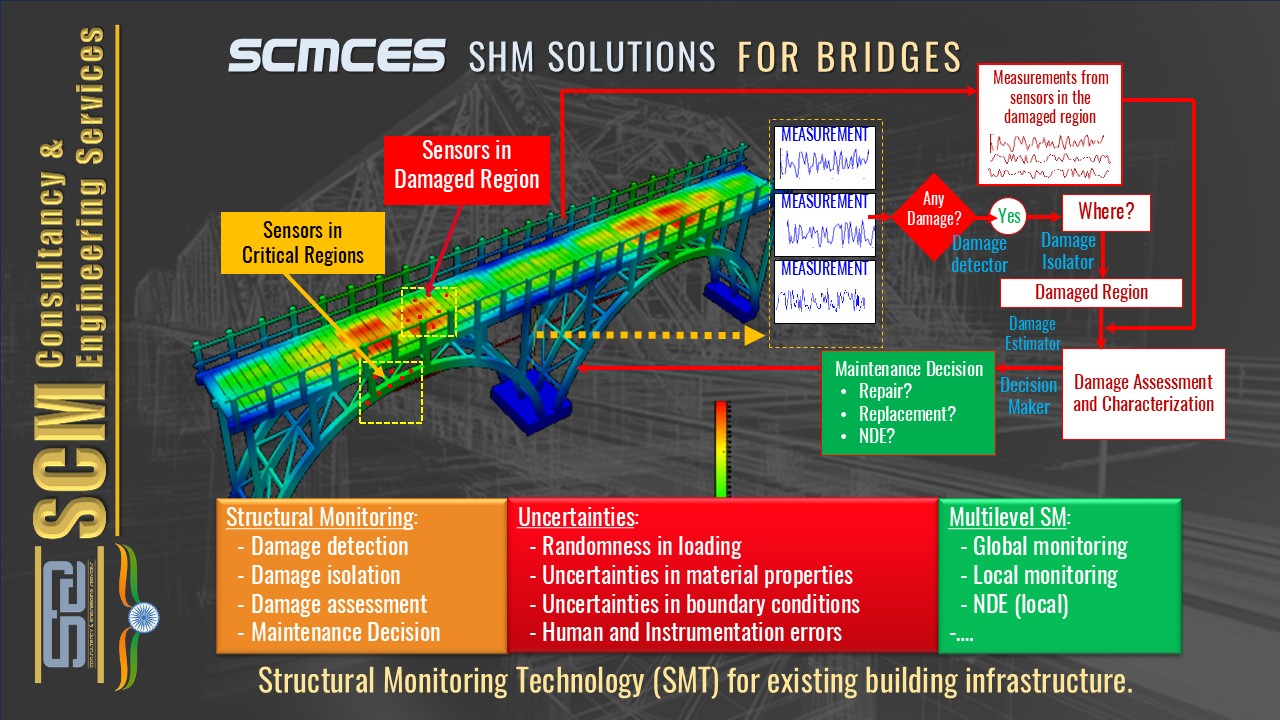

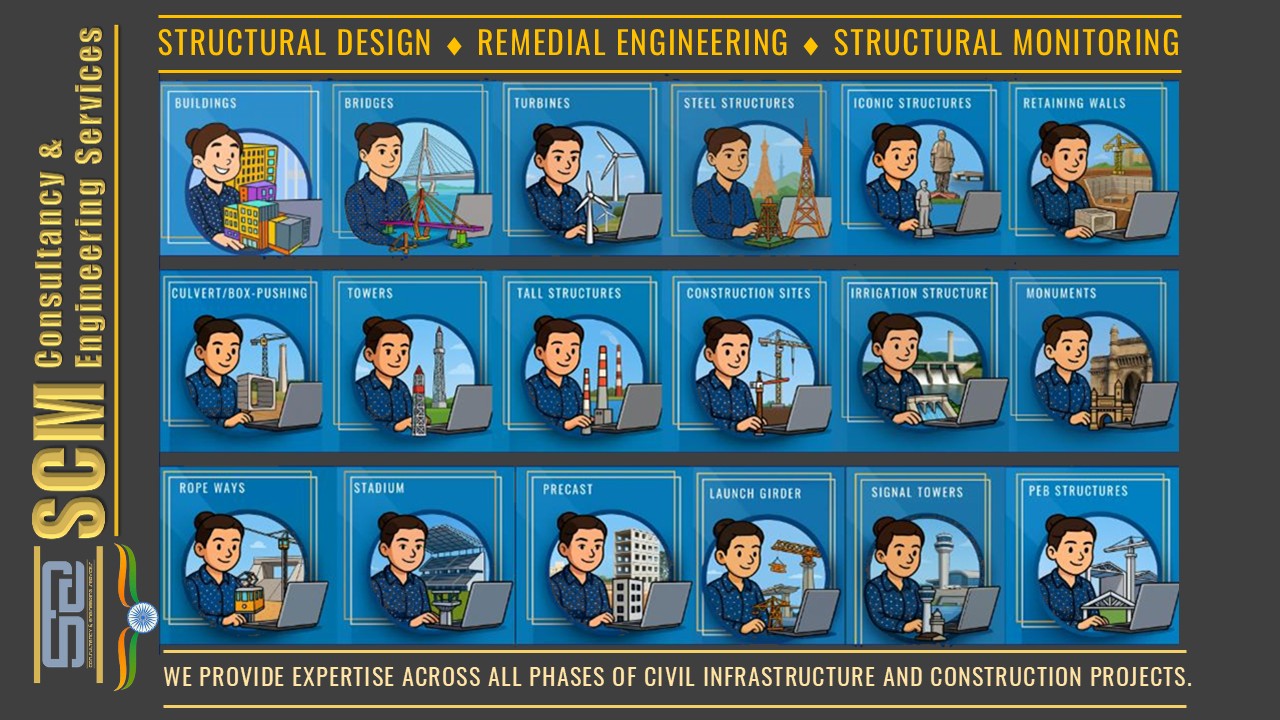

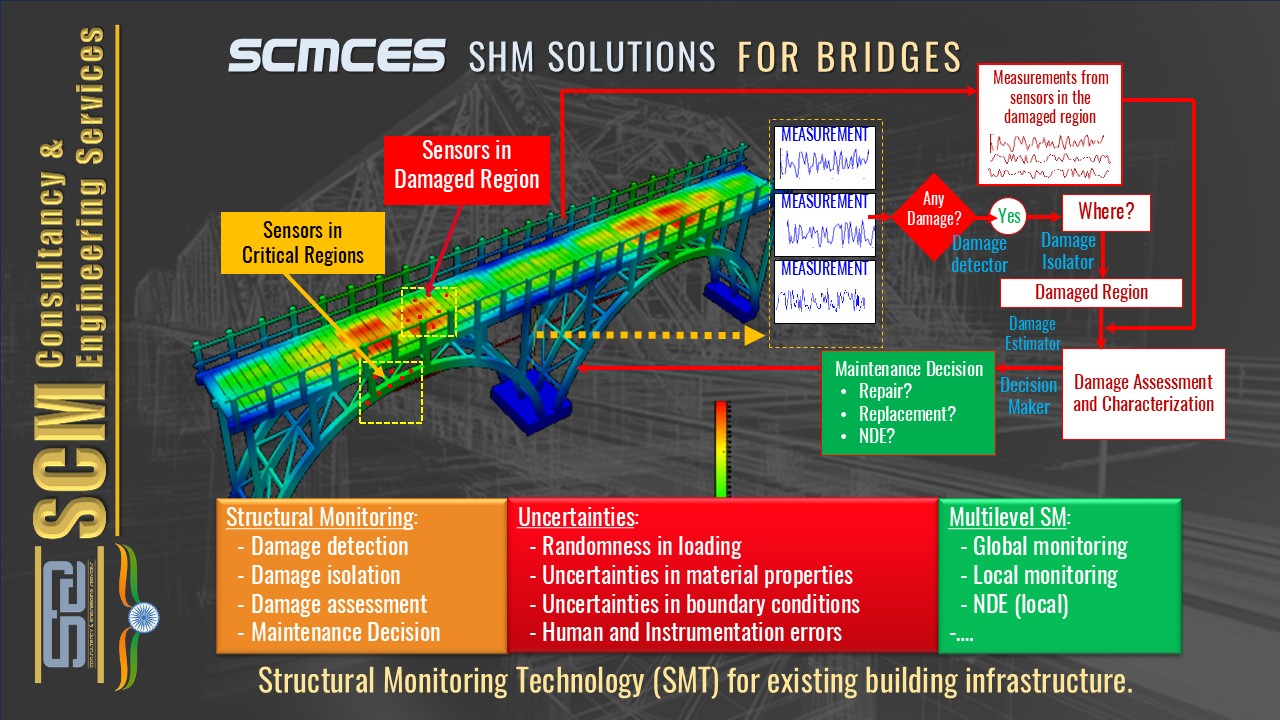

Bridge Monitoring Services

We offer Bridge Structural Health Monitoring solutions for:

- Highway and railway bridges

- Metro viaducts and flyovers

- Long-span and critical bridges

Bridge monitoring services include:

- Dynamic response and vibration monitoring

- Strain measurement and stress cycle evaluation

- Static and dynamic load testing

- Fatigue damage assessment

- Remaining service life estimation

- Bridge evaluation and performance rating

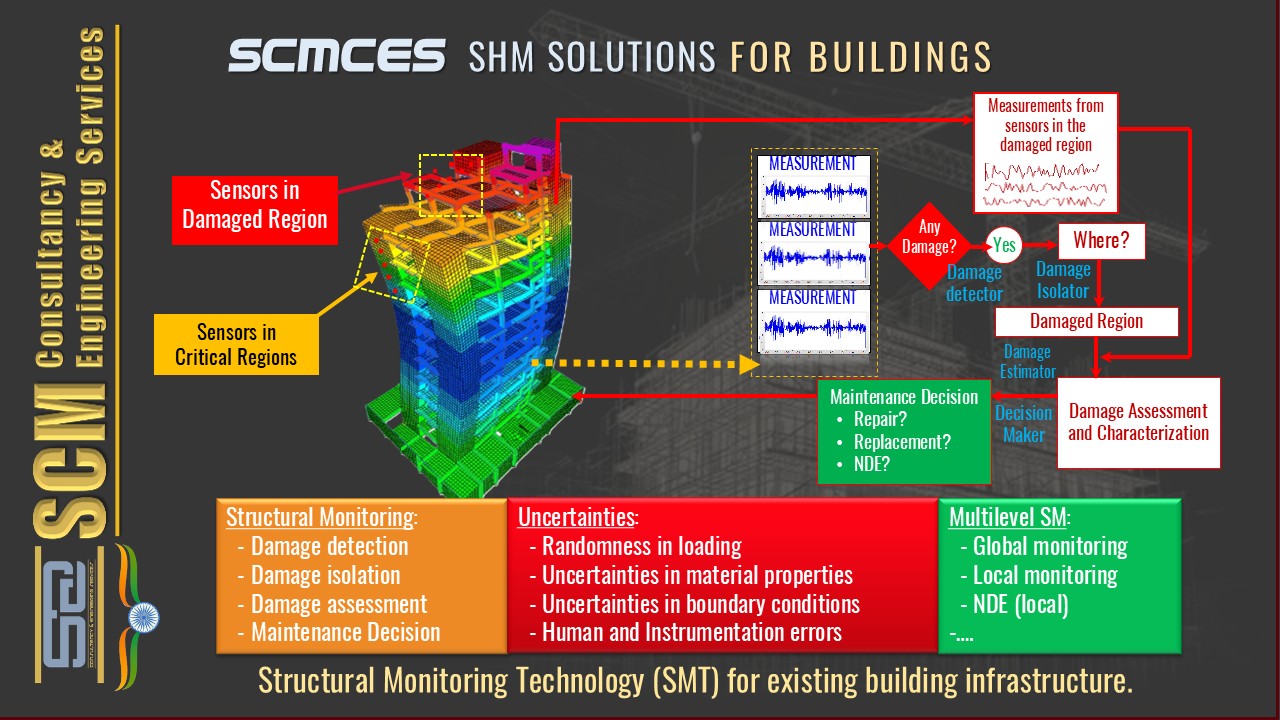

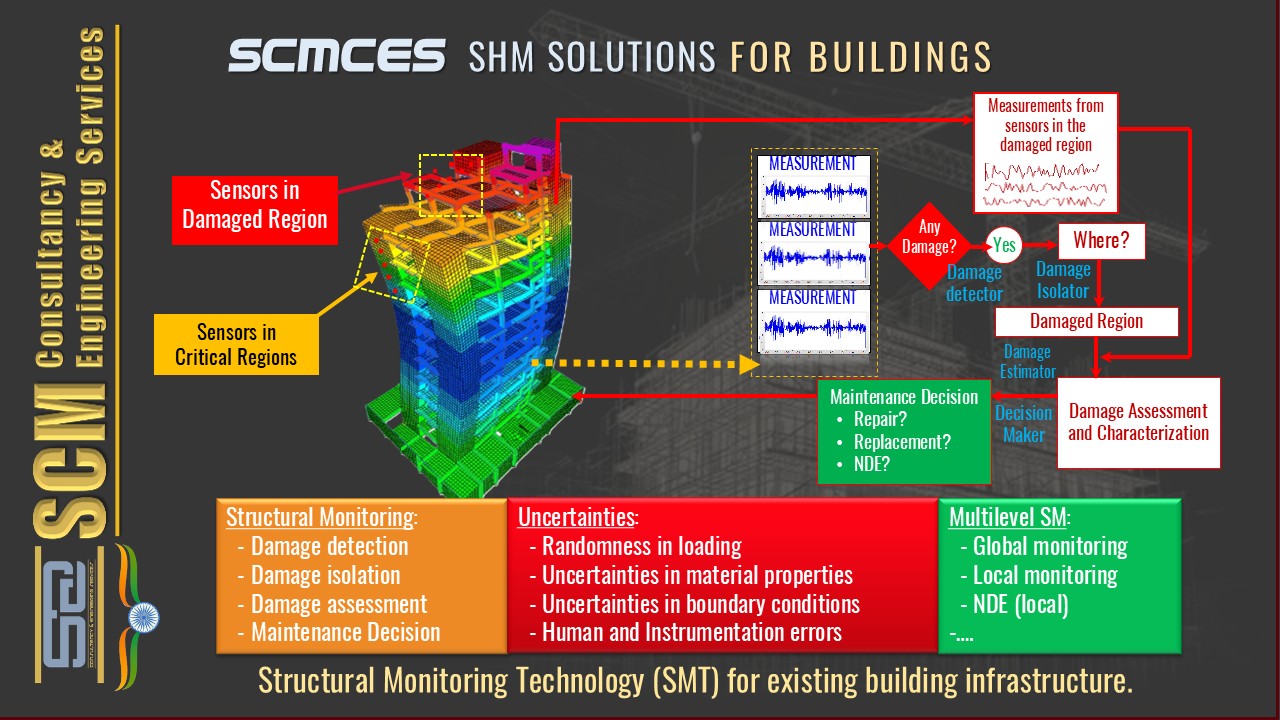

Building Vibration Monitoring

Building vibration monitoring is essential for structures affected by:

- Nearby construction and blasting

- Heavy machinery and turbines

- Traffic-induced vibrations

- Wind and seismic excitation

Our services include:

- Measurement of structural and floor vibrations

- Comfort and serviceability assessment

- Identification of resonance and amplification effects

- Long-term vibration trend analysis

- Recommendations for mitigation and retrofitting

Structural Monitoring Using Sensor Technology

SCMCES designs and deploys sensor-based structural monitoring systems, including:

- Accelerometers

- Strain gauges

- Displacement and tilt sensors

- Environmental sensors (temperature, humidity, wind, etc.)

Monitoring can be implemented as:

- Short-term monitoring (diagnostic studies)

- Long-term monitoring (continuous or periodic systems)

These systems complement conventional inspections and provide objective, measurable performance data.

Instrumentation Planning & SHM System Design

- Recommendation of instrumentation schemes tailored to each structure

- Selection of sensor locations based on structural behaviour

- Integration of data acquisition and communication systems

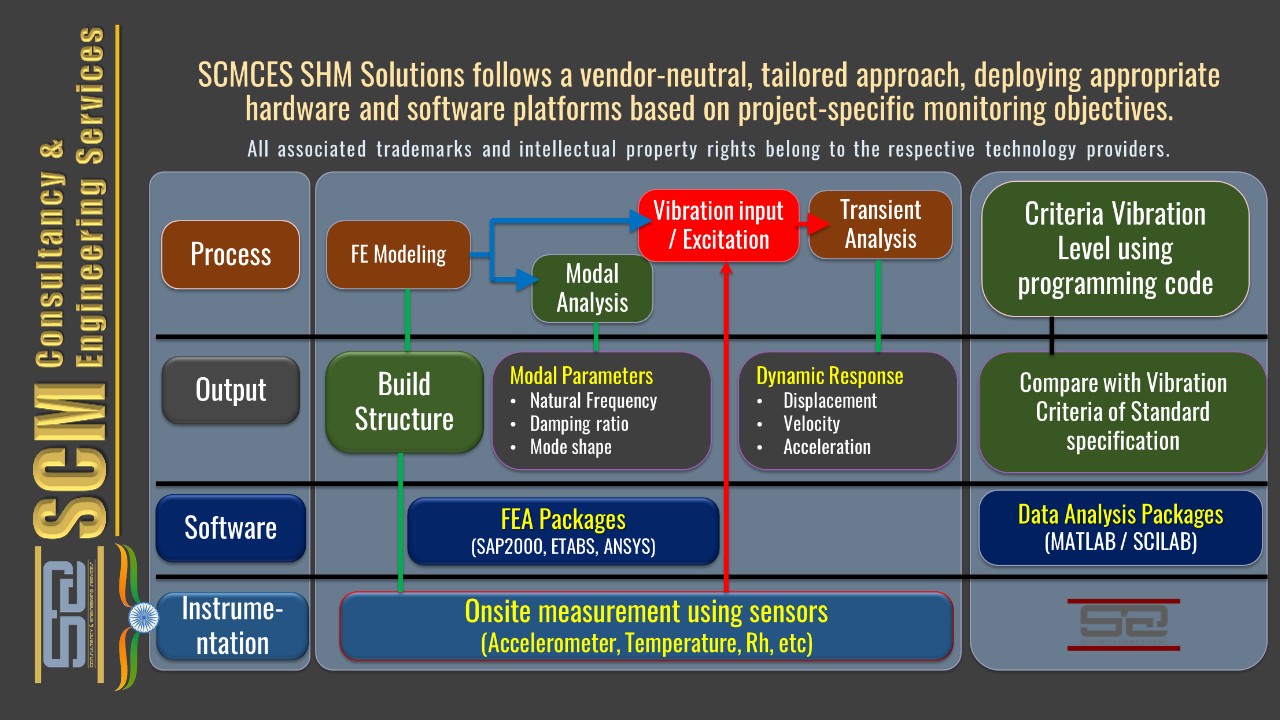

- Vendor-neutral approach to hardware and software selection

Structural Testing & Field Measurements

- Static and dynamic load testing

- Behavioural testing of bridges and buildings

- Field strain gauging for stress and fatigue evaluation

- Site-specific live load estimation based on measured response

Analytical & Numerical Structural Assessment

We integrate measured data with engineering analysis, including:

- Structural modelling and verification

- Finite Element Analysis (FEA)

- Correlation of analytical models with field measurements

- Performance evaluation under actual operating conditions

Fatigue, Durability & Remaining Life Assessment

We integrate measured data with engineering analysis, including:

- Fatigue damage assessment using real stress histories

- Identification of critical structural components

- Estimation of remaining service life

- Inputs for repair, strengthening, or rehabilitation decisions

Training & Capacity Building in SHM

SCMCES also provides training programs on Structural Health Monitoring, covering:

- SHM concepts and applications

- Sensor technologies and instrumentation

- Data interpretation and engineering decision-making

- Practical case studies from Indian infrastructure projects

Why Choose SCMCES for SHM Services

- Specialized expertise in Structural Health Monitoring & vibration assessment

- Experience with bridges, buildings, industrial and infrastructure projects

- Vendor-neutral, engineering-driven solutions

- Focus on actionable insights, not just data collection

- Integration of monitoring, testing, and analytical assessment